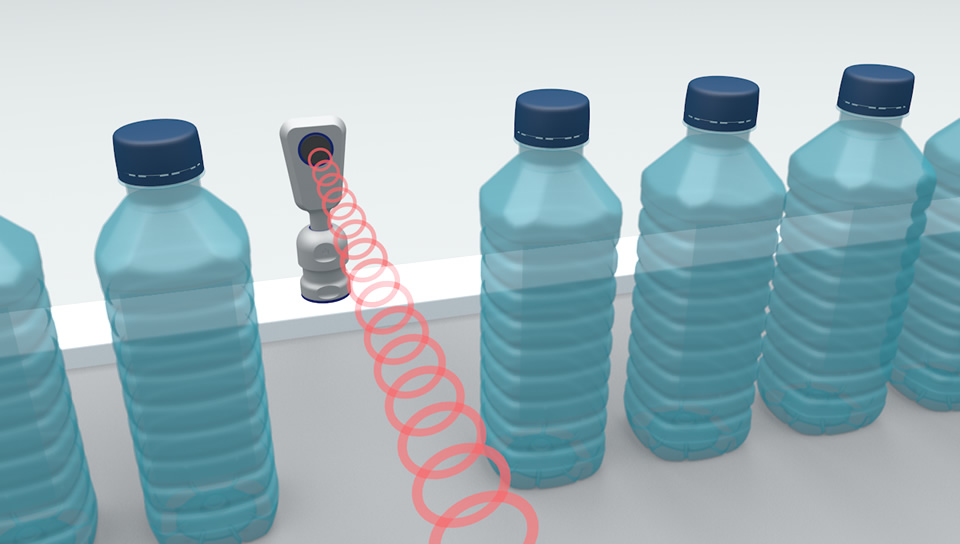

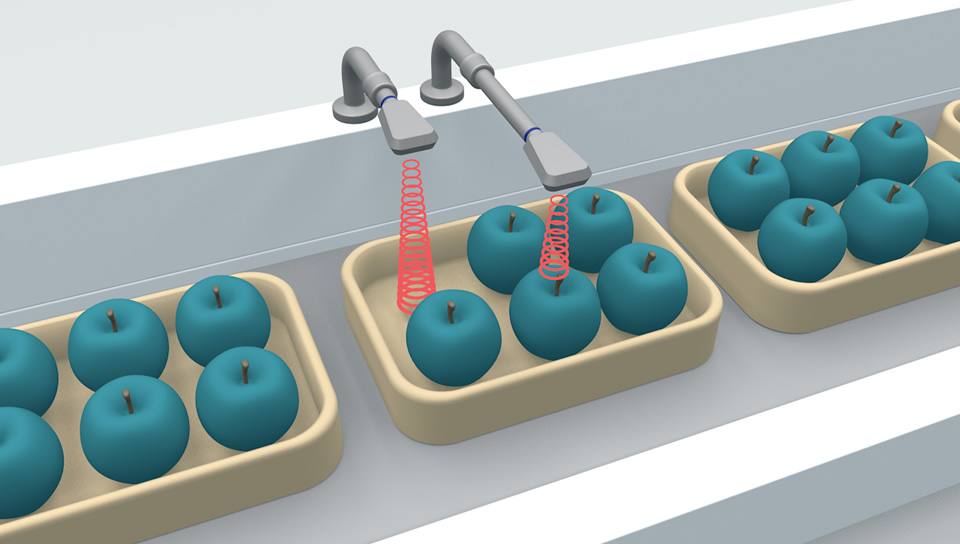

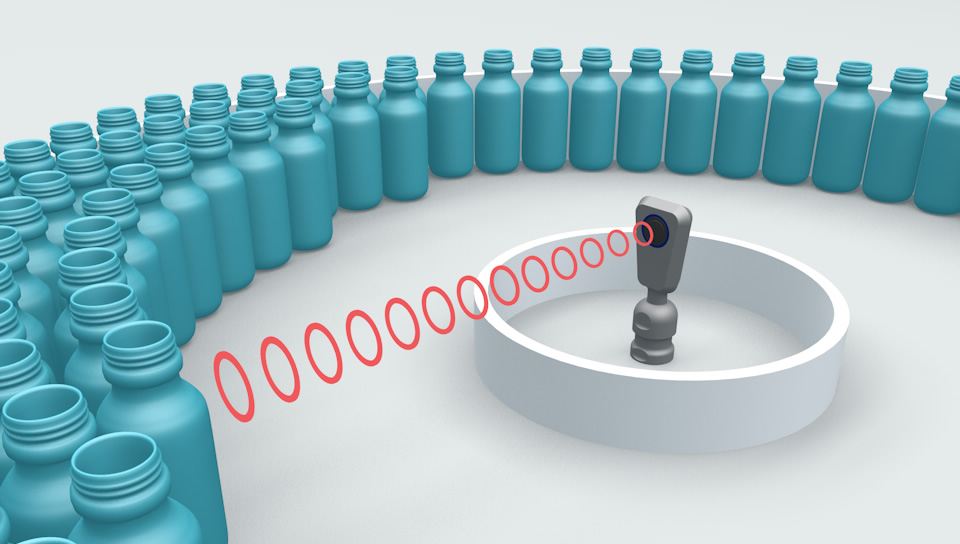

pms超声波传感器

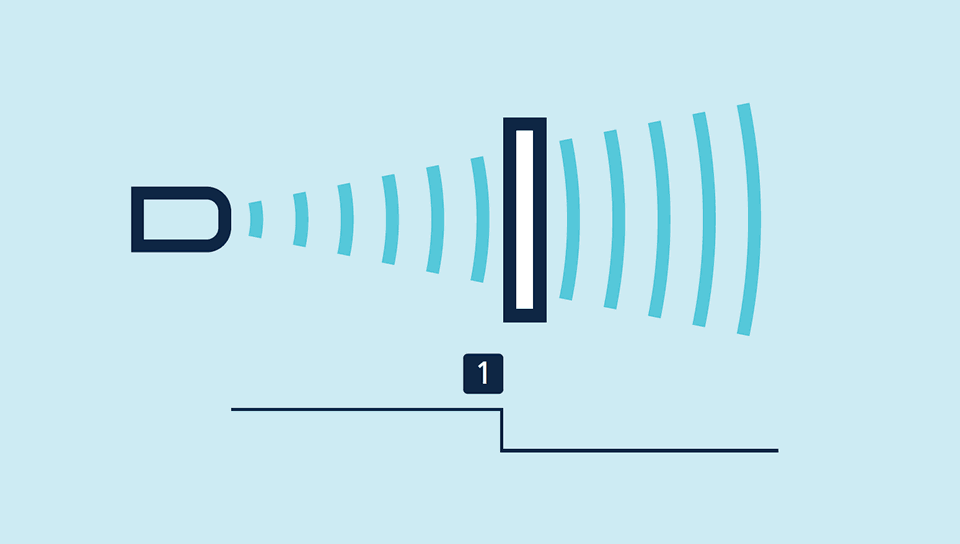

pms超声波传感器是根据EHEDG标准中最严苛的卫生要求而设计的。有2种不同型号传感器可用:D12适配杆式和D12插座式的。标准的带D12适配杆的传感器可以通过卫生螺纹BF-pms/A1或装配夹进行安装。

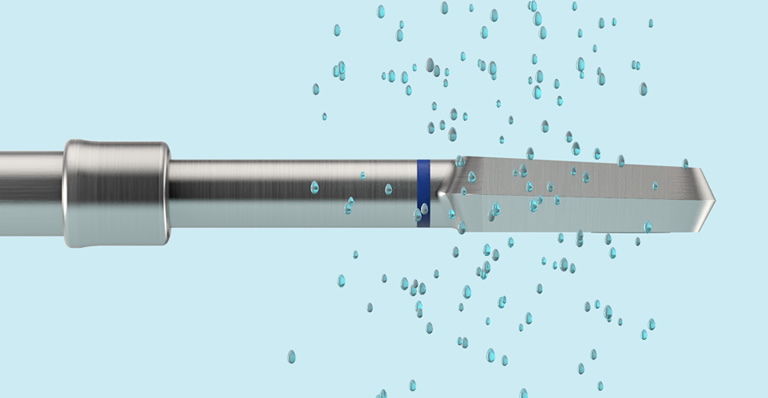

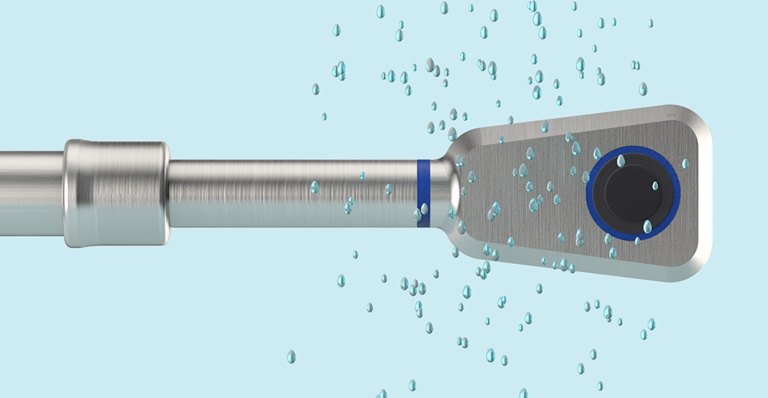

不锈钢外壳的创新设计确保PMS传感器可以在几乎所有可能想到的安装位置都没有水平表面。甚至水平安装,垂直向下检测,外壳背面依旧维持≥3°的角度。清洗液体可以顺利地从外壳流下。

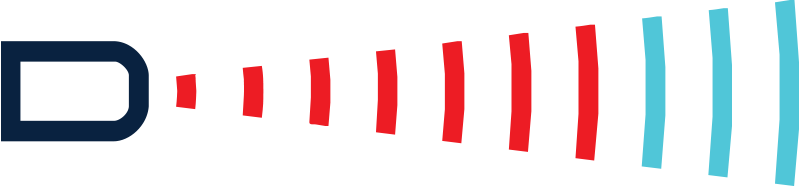

外壳后侧倾斜超过3°

光滑的不锈钢外壳无缝无边,其粗糙度Ra<0.8µm。除了传感器的设计,正确的选材也是至关重要的。超声波换能器由PTFE膜保护,可以抵抗化学腐蚀清洁剂与消毒剂的侵蚀。pms传感器经ECOLAB认证具有很高的耐久性。

不锈钢传感器具有清洗设计,所有水平表面至少倾斜3°。

pms卫生传感器

具有2种输出方式及4种检测范围:

|

1个有PNP和NPN技术的推挽输出 |

|

1个4-20mA或0-10V的模拟量输出 |