-

Afstandsensoren

- cilindrisch

- mic+

mic+ ultrasone sensoren

mic+ sensoren zijn in vier varianten met vijf afzonderlijke detectiewijdtes verkrijgbaar.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

6,0 m

6,0 m

- mic

mic ultrasone sensoren

Deze mic-sensoren in geheel metalen uitvoering zijn met vijf verschillende bedrijfsdetectiewijdten verkrijgbaar.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

6,0 m

6,0 m

- wms

wms ultrasone sensoren

wms sensors are ideal for customer-driven signal evaluation.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

6,0 m

6,0 m

- lpc+

lpc+ ultrasone sensoren

in M18 behuizing: 2 type uitgangen met IO-Link interface en Smart Sensor Profile.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,15 m

0,15 m

0,25 m

0,25 m

0,35 m

0,35 m

1,0 m

1,0 m

- nero

nero ultrasone sensoren

Ultrasoon sensor in de M18 behuizing: 4 detectie bereiken, 2 haaks of recht model, 2 uitgangssignalen.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,15 m

0,15 m

0,25 m

0,25 m

0,35 m

0,35 m

1,0 m

1,0 m

- pico+

pico+ ultrasone sensoren

De nieuwe ultrasoon sensor in de M18 behuizing: 4 detectie bereiken, 3 uitgangssignalen, haaks of recht model, IO-Link.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,15 m

0,15 m

0,25 m

0,25 m

0,35 m

0,35 m

1,0 m

1,0 m

- nano

nano ultrasone sensoren

nano – de naam zegt het al! Slechts 55 mm lang, inclusief connector, de nano is de meest korte M12 ultrasoon sensor in de markt.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,15 m

0,15 m

0,24 m

0,24 m

- mic+

- balkvormig

- cube

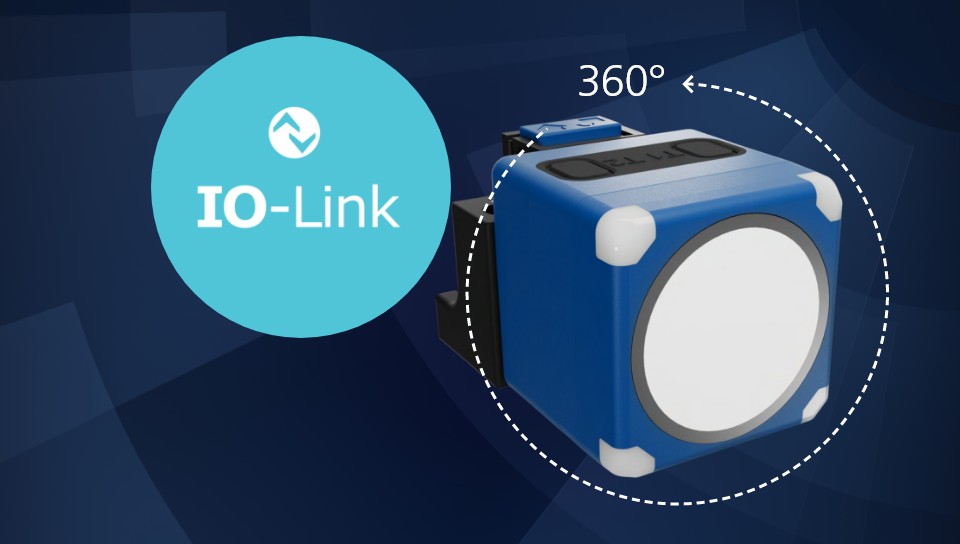

cube ultrasone sensoren

The cube sensors with rotatable sensor head and analogue or switching output + IO-Link.

- Uitgangen:

- Detectieafstanden:

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

- lcs+

lcs+ ultrasone sensoren

De nieuwe lcs+ultrasoon sensoren in de compacte balkvormige behuizing – met analoge/schakeluitgang + IO-Link.

- Uitgangen:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

6,0 m

6,0 m

- lcs

lcs ultrasone sensoren

Ultrasone sensoren van de lcs serie verkrijgt u in drie toestelvarianten met drie uiteenlopende bedrijfsdetectiewijdten.

- Uitgangen:

- Detectieafstanden:

0,25 m

0,25 m 0,35 m

0,35 m 1,3 m

1,3 m

- sks

sks ultrasone sensoren

Onze „kleinste": De sks sensor in een kubusvormige behuizing.

- Uitgangen:

- Detectieafstanden:

0,15 m

0,15 m

- ucs

ucs ultrasone sensoren

De ucs-sensoren in een robuuste metalen behuizing zijn mechanisch compatibel met de industriële standaard van de optische sensoren.

- Uitgangen:

- Detectieafstanden:

0,15 m

0,15 m 0,24 m

0,24 m

- zws

zws ultrasone sensoren

De zws-sensoren behoren tot de kleinste beschikbare ultrasone sensoren in een kubusvormige behuizing met Teach-in-taster.

- Uitgangen:

- Detectieafstanden:

0,07 m

0,07 m 0,15 m

0,15 m 0,24 m

0,24 m 0,25 m

0,25 m 0,35 m

0,35 m 0,7 m

0,7 m

- cube

- chemicalienbestendig

- pico+TF

pico+TF ultrasone vulgraad sensoren

De pico+TF sensoren zijn ideaal voor het contactloos meten van niveaus van chemisch agressieve vloeistoffen of granulaten.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,15 m

0,15 m

0,25 m

0,25 m

0,35 m

0,35 m

1,0 m

1,0 m

- crm+

crm+ ultrasone sensoren

Dubbel+ voor uw toepassing: het allround talent crm+ in roestvrij staal en met folie beklede omvormer.

- Uitgangen:

- Schroefdraadbehuizing:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

6,0 m

6,0 m

- hps+

hps+ ultrasone sensoren

De ultrasoon omvormers van de drukvaste hps+ sensoren zijn nu standaard met een PTFE folie beschermd.

- Uitgangen:

- Procesaansluiting:

- Detectieafstanden:

0,25 m

0,25 m

0,35 m

0,35 m

1,3 m

1,3 m

3,4 m

3,4 m

- pico+TF

- Hygienic Design

- pms

pms ultrasone sensoren

The design of the wash-down stainless steel housing with no crevices and dirt edges makes pms sensor perfectly suited to intensive cleaning and disinfection.

- Uitgangen:

- Detectieafstanden:

0,15 m

0,15 m

0,25 m

0,25 m

0,35 m

0,35 m

1,0 m

1,0 m

- pms

- cilindrisch

-

Speciale sensoren

- Baankantensensoren

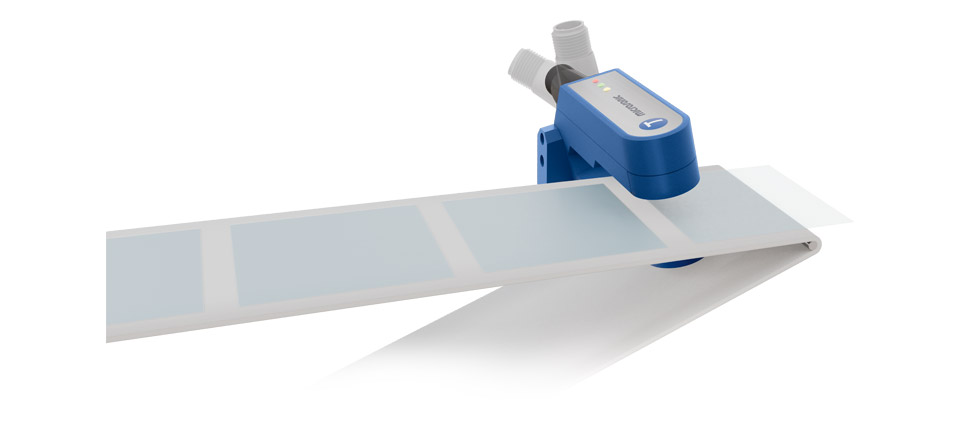

- bks+

bks+ ultrasone baankantensensoren

Met de kantensensor kunnen baankranten van folie, papier en andere geluidondoorlaatbare materialen contactloos gedetecteerd worden.

- Uitgangen:

- bks

bks ultrasone kantensensor

Met de kantensensor kunnen baankranten van folie, papier en andere geluidondoorlaatbare materialen contactloos gedetecteerd worden.

- Uitgangen:

- bks+

- Dubbelelaagdetectie

- dbk+4

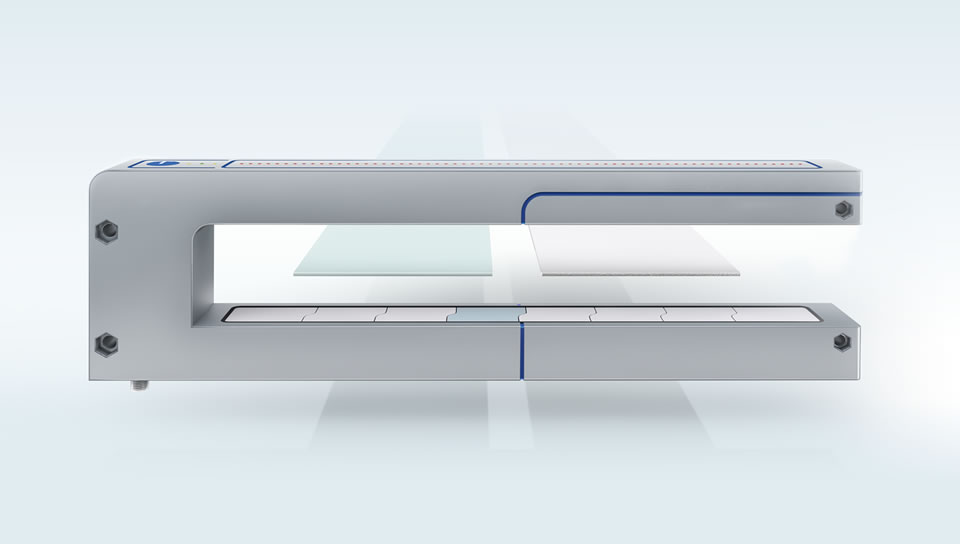

dbk+4 ultrasone dubbelelaagdetectie

Ultrasoon dubbelelaagcontrole van de meest recente aard. Vier varianten: voor alle denkbare inbouwsituaties.

- Uitgangen:

- Schroefdraadbehuizing:

- dbk+5

dbk+5 ultrasone dubbelelaagdetectie

Ultrasoon dubbelelaagcontrole van de meest recente aard..

- Uitgangen:

- Schroefdraadbehuizing:

- dbk+4

- Label- en Splicesensoren

- Zender/ontvanger sensoren

- ews

ews zender/ontvanger ultrasoon sensoren

Ultrasoon zender/ontvanger sensoren voor contactloze detectie van objecten.

- Uitgangen:

- Schroefdraadbehuizing:

- ews

- Baankantensensoren

- Toebehoren

- Ondersteuning

- Over ons

-

- bestelling

- zoeken op volledige tekst

- bestelling