The bks+ ultrasonic web edge sensor

is a fork sensor for scanning the edges of sound-impermeable materials such as foil or paper.

This is why the bks+ is ideally suited for the web control of high-transparency foils, light-sensitive materials, materials with greatly varying transparency and paper subject to high paper dust loads.

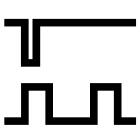

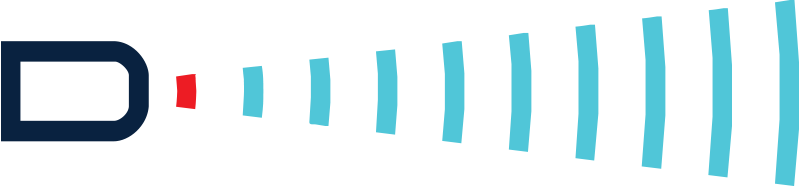

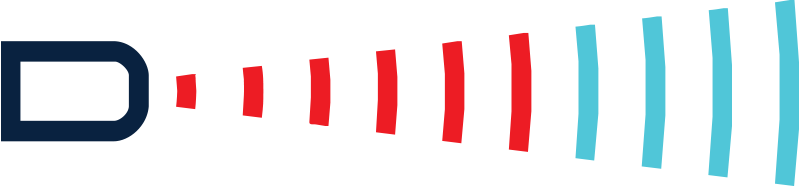

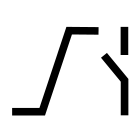

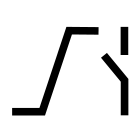

The functional principle

Both transducer and receiver are placed in a single, slim fork housing. The transducer in the lower leg is emits short, cyclical sound pulses. These are detected by the ultrasonic receiver in the upper leg of the fork. A material embedded in the fork covers the sound gap and thereby dampens the receiving signal in depending on the coverage. This is analysed by internal electronics.

An analogue signal is output depending of coverage, resp. data word via IO-Link.

|

1 Push-Pull switching output with pnp or npn switching technology and 1 analogue output 4–20 mA and 0–10 V |

The working range for the bks+3/FIU/A is 12 mm and for the bks+6/FIU/A is 40 mm.