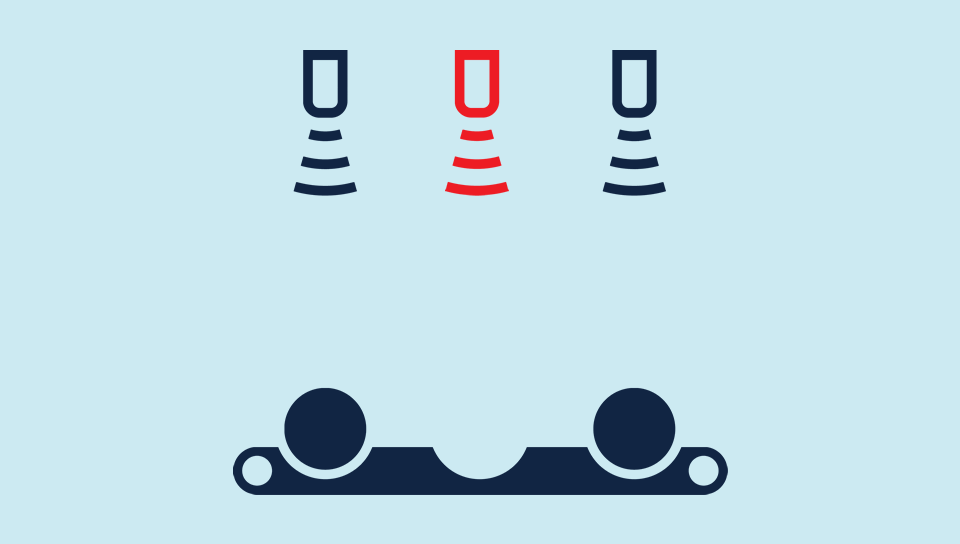

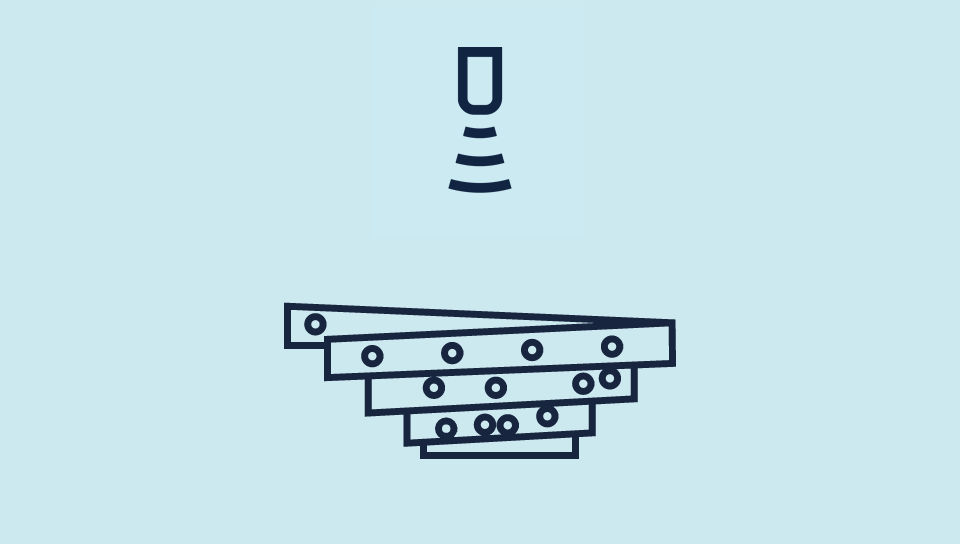

Different operating modes and device configurations enable microsonic sensors to be used in all conceivable automation applications.

-

Distance sensors

- cylindrical

- mic+

mic+ ultrasonic sensors

mic+ sensors are available in four unit variants with five different detection ranges.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.25 m

0.25 m

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

6.0 m

6.0 m

- mic

mic ultrasonic sensors

These completely metal mic sensors are available in two device designs with five different detection ranges.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.25 m

0.25 m

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

6.0 m

6.0 m

- wms

wms ultrasonic sensors

wms sensors are ideal for customer-driven signal evaluation.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.25 m

0.25 m

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

6.0 m

6.0 m

- lpc+

lpc+ ultrasonic sensors

in M18 housing: 2 output stages with IO-Link interface and Smart Sensor Profile.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.15 m

0.15 m

0.25 m

0.25 m

0.35 m

0.35 m

1.0 m

1.0 m

- nero

nero ultrasonic sensors

In M18 housing: 4 ranges, 2 housing’s designs and 2 operating modes.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.15 m

0.15 m

0.25 m

0.25 m

0.35 m

0.35 m

1.0 m

1.0 m

- pico+

pico+ ultrasonic sensors

The new M18 ultrasonic sensor: 4 ranges, 3 operating modes, 2 housing’s designs, 1 IO-Link interface.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.15 m

0.15 m

0.25 m

0.25 m

0.35 m

0.35 m

1,0 m

1,0 m

- nano

nano ultrasonic sensors

nano – what‘s in a name? At just 55 mm long, including plug, the nano is the shortest M12 ultrasonic sensor on the market.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.15 m

0.15 m

0.24 m

0.24 m

- mic+

- cuboidal

- cube

cube ultrasonic sensors

The cube sensors with rotatable sensor head and analogue or switching output + IO-Link.

- Outputs:

- Detection ranges:

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

- lcs+

lcs+ ultrasonic sensors

The lcs+ ultrasonic sensors come in a very compact square-shaped housing - with analogue or switching output + IO-Link.

- Outputs:

- Detection ranges:

3.4 m

3.4 m 6.0 m

6.0 m

- lcs

lcs ultrasonic sensors

Ultrasonic sensors of the lcs serie are available in three device variants with three different operating ranges.

- Outputs:

- Detection ranges:

0.25 m

0.25 m 0.35 m

0.35 m 1.3 m

1.3 m

- sks

sks ultrasonic sensors

The smallest of its kind: The sks sensor in cubical housing.

- Outputs:

- Detection ranges:

0.15 m

0.15 m

- ucs

ucs ultrasonic sensors

The ucs sensors in a sturdy metal housing are mechanically compatible with the industrial standard of opto sensors.

- Outputs:

- Detection ranges:

0.15 m

0.15 m 0.24 m

0.24 m

- zws

zws ultrasonic sensors

The zws sensors featuring a cubical housing and a teach-in button are among the market's smallest available ultrasonic sensors.

- Outputs:

- Detection ranges:

0.07 m

0.07 m 0.15 m

0.15 m 0.24 m

0.24 m 0.25 m

0.25 m 0.35 m

0.35 m 0.7 m

0.7 m

- cube

- chemical-resistant

- pico+TF

pico+TF ultrasonic filling-level sensor

The pico+TF sensors are ideal for the non-contact fill level measurement of chemically aggressive liquids or granules.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.15 m

0.15 m

0.25 m

0.25 m

0.35 m

0.35 m

1.0 m

1.0 m

- crm+

crm+ ultrasonic sensors

The allround talent crm+ in stainless steel 1.4571 and with film-coated transducer.

- Outputs:

- Threaded sleeve:

- Detection ranges:

0.25 m

0.25 m

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

6.0 m

6.0 m

- hps+

hps+ ultrasonic sensors

The ultrasonic transducers of the pressure-resistant hps+ sensors are now fitted out - as standard - with a PTFE film.

- Outputs:

- Process connection:

- Detection ranges:

0.25 m

0.25 m

0.35 m

0.35 m

1.3 m

1.3 m

3.4 m

3.4 m

- pico+TF

- Hygienic Design

- pms

pms ultrasonic sensors

The design of the wash-down stainless steel housing with no crevices and dirt edges makes pms sensor perfectly suited to intensive cleaning and disinfection.

- Outputs:

- Detection ranges:

0.15 m

0.15 m

0.25 m

0.25 m

0.35 m

0.35 m

1,0 m

1,0 m

- pms

- cylindrical

-

Special sensors

- Web edge sensors

- bks+

bks+ ultrasonic web edge sensors

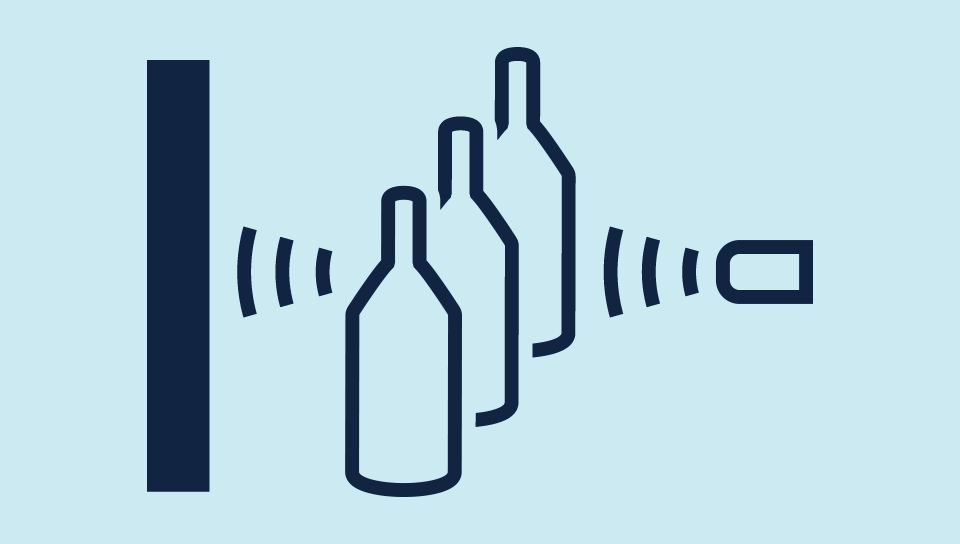

The bks+ edge sensor facilitates the contact-free web edge scanning of foils, paper and other soundimpermeable materials.

- Outputs:

- bks

bks ultrasonic edge sensors

The bks edge sensor facilitates the contact-free web edge scanning of foils, paper and other soundimpermeable materials.

- Output:

- bks+

- Double sheet control

- Label and splice sensors

- Through-beam barrier

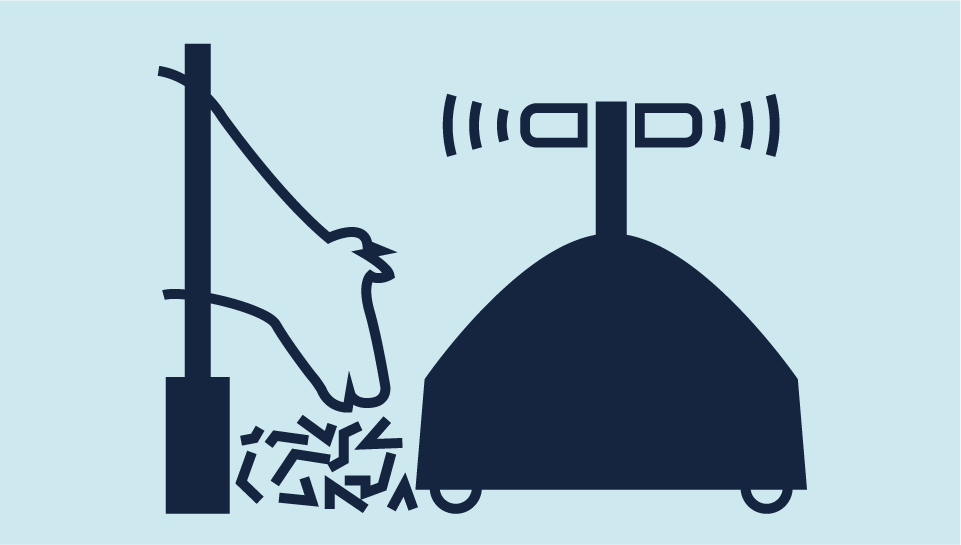

- ews

ews ultrasonic through-beam barrier

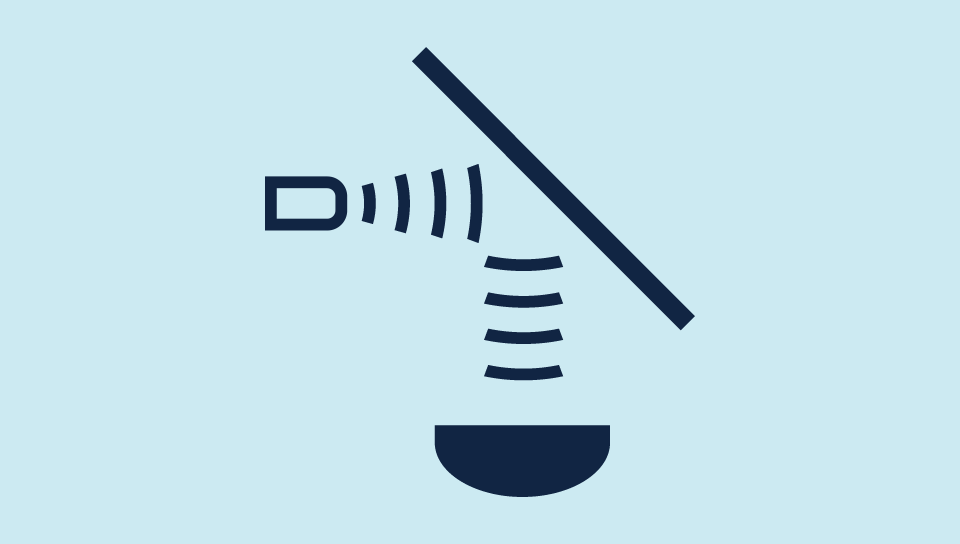

Ultrasonic through-beam barrier for contact free detection of objects.

- Output:

- Threaded sleeve:

- ews

- Web edge sensors

- Accessories

- Support

- About microsonic

-

- order no.

- full-text search

- order no.